Do you know where your grease trap waste ends up?

For many food businesses, once the grease trap has been emptied, the job feels finished. The drains are clear, production continues and the waste is gone. But is it really?

Every litre of fat, oil and grease (FOG) waste collected from your site has a destination. If it is not taken to a licensed recycling facility, your business can still be responsible for what happens next.

Why it matters

Grease trap waste that is not handled correctly does not disappear. It can end up poured into sewers, mixed with other waste, or dumped illegally. When this happens, it contributes to blockages and pollution incidents.

Under UK law, the producer of the waste remains responsible until it is safely and legally disposed of, even if a contractor removes it. This is part of your Duty of Care under the Environmental Protection Act 1990.

If your waste causes a pollution incident, both you and your contractor could face fines or enforcement action from the Environment Agency or your local water company.

Your legal obligations

Food manufacturers, processors and producers have a legal duty to comply with regulations controlling FOG waste.

Water Industry Act 1991, Section 111

It is an offence to discharge anything into public sewers that may cause blockages or interfere with flow.

Section 111 Restrictions on use of public sewers

Environmental Protection Act 1990

All businesses must store, transport and dispose of waste safely through licensed carriers.

Dispose of business or commercial waste

Building Regulations (Approved Document H)

Commercial hot food premises should install grease separators or other effective means of preventing FOG from entering drains.

Failure to meet these obligations can result in fines, clean-up costs and possible prosecution.

If your grease trap isn’t emptied often enough, it can overflow, block drains and lead to costly pollution fines.

What you are liable for

-

-

Installation and maintenance

If your site does not have a suitable grease trap or it is not serviced regularly, you may be liable for any resulting damage or blockages. -

Waste disposal chain

Even if you use a contractor, you are responsible for ensuring they are licensed and that the waste goes to an approved facility. -

Records and proof

You must keep waste transfer notes and documentation showing how your FOG waste is handled and where it goes. -

Environmental impact

Illegal dumping or poor management can lead to pollution, odour problems and damage to local infrastructure, all traceable back to your business.

-

What you should do

-

-

Check your contractors

Ask for their waste carrier licence and the permit of the facility they use.

Check a waste carrier licence here -

Keep records

Keep copies of all waste transfer notes for at least two years. These must include details of what was collected, when, by whom and where it went. -

Schedule regular maintenance

Grease traps should be emptied and cleaned on a regular schedule depending on kitchen use. For high-output sites, this could mean every four to six weeks. -

Ask where your waste goes

Responsible contractors will tell you exactly where the waste is recycled or processed. If they cannot, that is a red flag. - Choose recycling

When grease trap waste is recycled through licensed FOG recovery facilities, it can be converted into renewable biofuel feedstock rather than sent to landfill.

-

In summary

If you cannot confidently answer the question “Where does our grease trap waste go?” it is time to find out. Poor management of FOG waste risks more than your drains. It can lead to fines, reputational damage and environmental harm.

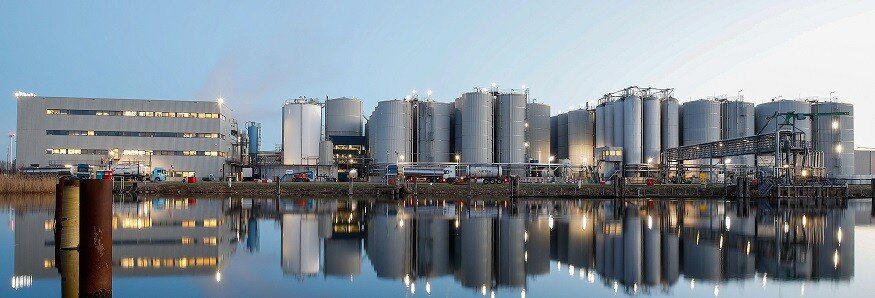

At Eco Clarity, we work with food manufacturers, producers and waste management companies to make sure grease trap waste is tracked, recycled and turned into renewable energy. This helps businesses stay compliant and be more sustainable.

Ready to recover more from your waste?

We’re helping businesses across the UK turn FOG and GRU waste into renewable value.

Recent Comments