Why FOG management matters for food factories

For modern food manufacturers, managing fat, oil and grease (FOG) waste is essential. Effective FOG recovery supports environmental responsibility, ensures compliance with regulations and can reduce operational costs.

In sectors like meat, dairy and fish processing, large volumes of by-product waste are produced every year. Fish processing alone generates around 133,000 tonnes of by-product waste annually (FAO, Fish Value Chains). Heads, bones, skins and residual oils all contain high levels of fat and oil that, if not properly treated, can enter wastewater streams.

Once in drains and sewers, these fats and oils solidify, creating blockages, fatbergs and wider public health risks (UK Parliament Research Briefing). With the Environment Act 2021 phasing out food waste to landfill and tighter controls under the Water Industry Act 1991, food factories need robust FOG waste solutions or risk fines, reputational damage and costly disruptions.

Environmental and regulatory requirements for FOG

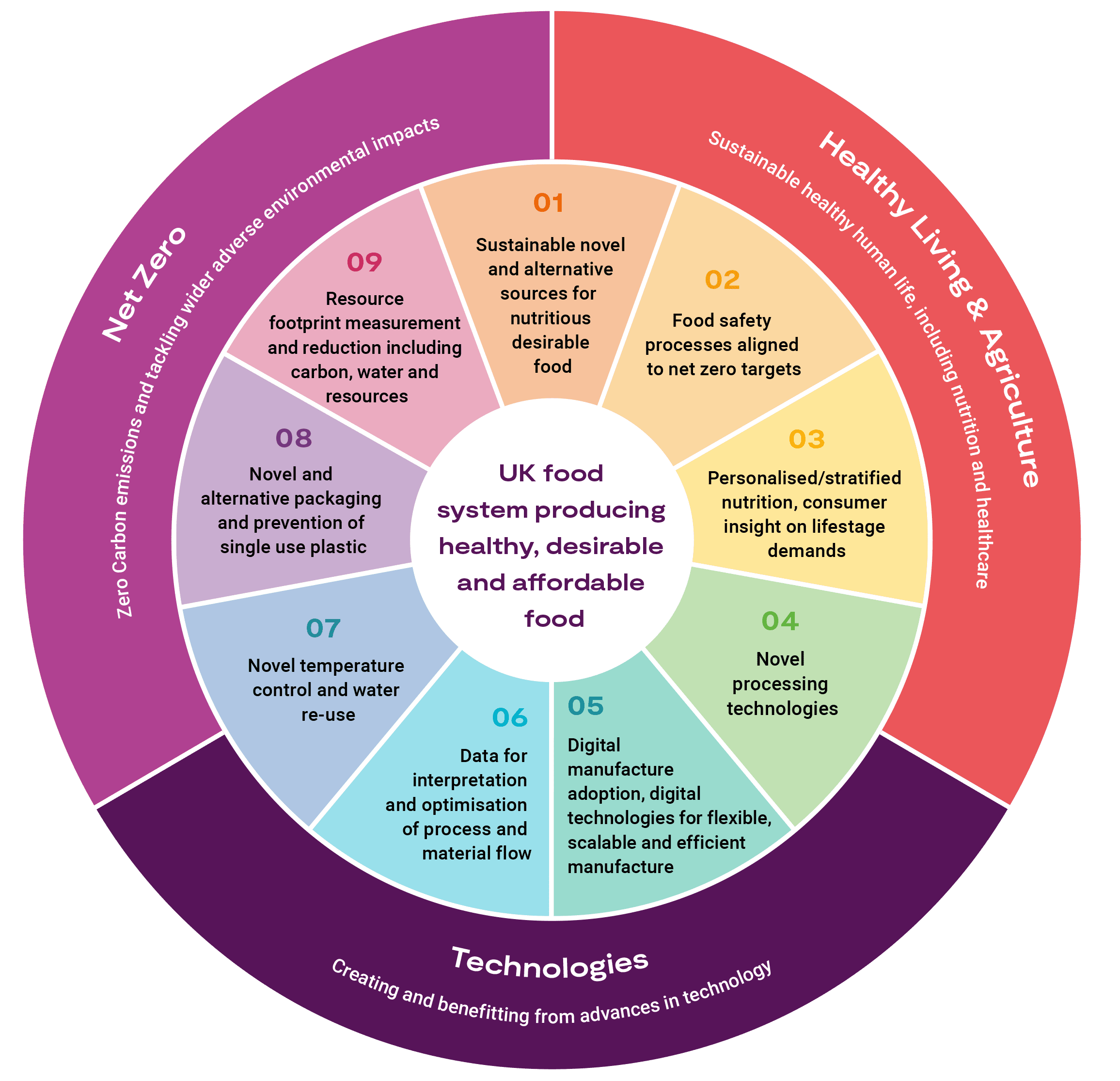

Every food business in the UK has a legal obligation under Section 111 of the Water Industry Act to prevent the discharge of fats, oils and grease (FOG). However, compliance is just one aspect of the broader responsibility. Investors, customers and regulators are increasingly expecting businesses to showcase:

Benefits of sustainable FOG management for manufacturers

Sustainable FOG management goes beyond compliance and delivers measurable value.

- Lower costs and risks Avoid unplanned downtime and expensive drainage repairs.

- Carbon savings Each tonne of FOG recovered through Eco Clarity typically saves up to 2.34 tonnes of CO₂e.

- Green credentials Demonstrate circular economy leadership and meet investor expectations for ESG performance.

- Energy recovery FOG is repurposed into high-grade biodiesel feedstock, cutting reliance on fossil fuels.

Source: Innovate UK Business Connect

Eco Clarity’s FOG waste recovery process

Eco Clarity provides a flexible FOG waste solution that integrates seamlessly with your operations. Depending on your setup, we can support your business through:

1. Off-site recovery at national Eco Clarity hubs

We work with your licensed waste contractors to collect FOG from grease traps and interceptors across single or multi-site facilities.

Every load is sampled and logged with documentation to simplify audits and support ESG reporting.

2. On-site hub for cleaner water and value recovery

An Eco Clarity hub can be installed directly at your facility, giving you cleaner wastewater discharge and the highest level of FOG recovery.

This maximises sustainability impact while reducing operational risks. Find out more

FOG waste is transported to Eco Clarity hubs, where it is transformed from waste into valuable renewable resource

Turn FOG waste into renewable energy and carbon savings

FOG does not have to be a problem. With Eco Clarity, it becomes a renewable resource that helps your business cut costs, reduce emissions and prove your sustainability impact.

Contact Eco Clarity today to arrange a site audit, estimate your annual FOG waste volumes, and discover how our FOG waste solutions can drive environmental and financial performance in your food manufacturing or processing facility.

Recent Comments